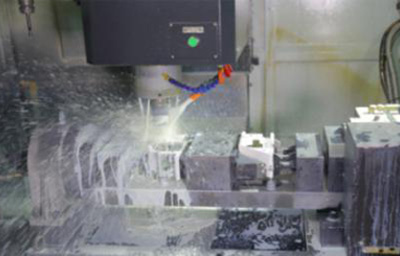

Because upstream industries for embroidery equipment is a sprawling, elaborate industry, most key machine components need to be purchased from various international locations, making it difficult to control machine quality and raw material quality, which in turn leads to difficulties maintaining the processing quality, increases processing costs, and lowers machine part quality. Unlike most, however, and avoiding all of those problems, Promaker produces nearly all key precision components here in house in a machining workshop spanning4500㎡. This facility is equipped with 85 sets of high precision vertical and horizontal machining centers, 20 sets of lathers, grinders, millers, CNC bending machines and CNC punching machines.

A durable and reliable machine body and structure ensure an embroidering machine features a long service life. At Promaker, we believe the best machine structure cannot be obtained unless made with an exceptional design, high quality raw materials, and advanced materials. That is why we spent 10 million CNY to introduce an advanced shot blasting and descaling line into our production factory, ensuring the machine body is processed using a 16 high powered shot blasting head to ensure the smooth and bright surface. Our machines are then coated with a highly corrosion resistant, solid and low adhesive primer, which is also excellent preparation for later surface coating. A gantry machining center also ensures machine body precision.

Promaker invested 10 million CNY on an advanced painting workshop. It is here that the water revolving spray painting and absorption-desorption combustion equipment result in an environmentally friendly performance, high quality primer, and an excellent surface coating spraying effect.

Promaker’s assembly workshop is an advanced management and assembly facility, using a PDCA (plan, do, check, act) method for quality control. With such an extensive space, more than 250 embroidery machine sets are simultaneously assembled, while the workshop is also equipped with a customized profile processing line, customized table processing line and line-side warehouse to ensure material supply. providing. As the last step before product delivery, our assembly workshop guarantees a high product quality delivery to every customer, no matter where they are in the world.